|

Tribology Group: An Overview of Current Activities

Group Leader: Margaret Stack

General Introduction: What we do in this group.... Tribology is a derivation of the Greek word "Tribos" which means "rubbing". The activities of this research group cover areas where:

In particular, their interactions with corrosion (tribo-corrosion) are being examined and the rationale for defining such interactions-so important for Engineers charged with controlling such processes-is being studied. Significant progress has been made in the past 10 years in the UK in the study of tribological phenomena, particularly in the areas of erosion-corrosion and abrasion and the development of engineering "maps" of such processes. This group is concerned with developing maps for particulate erosion, micro-abrasion, sliding wear and cavitation, in corrosive environments, both at room and at elevated temperatures. It has an established track record in mapping slurry erosion-corrosion of coated and uncoated materials, solid particle erosion of MMCs at elevated temperatures, and for erosion-corrosion of new generation "superlattice" coatings. These maps may indicate a wide range of phenomena i.e. the mechanism of wear, the extent of wastage and interaction between the processes, all components of tackling the complex area of Tribology from the perspective of the Mechanical Engineer. Over 110 papers have been generated on this work to date. The first edition of Tribologia, a newsletter of the research and conference activities of students involved in the group has just been produced. The group is home to the EPSRC funded network on tribo-corrosion: TrICorr-Net: http://www.tricorrnet.strath.ac.uk/ . Facilities The Tribology facilities in the Department of Mechanical Engineering include some of the latest state-of-the art equipment in this area which has been designed in universities throughout the UK i.e. Impinging Jet Erosion Apparatus with electrochemical interface for measuring corrosion current densities during the erosion test.(Velocity range, 1-12 m/s, particle size range from 50um to 1mm). ACM potentiostat with computer controlled data acquisition system. This is a test widely used to simulate erosion-corrosion of components for offshore applications. Erosion-corrosion mechanism maps, for various material/parameter combinations, are being generated based on the experimental results from the test programme, and the extent of "synergy" between the two processes may be identified using such results.

Impinging Jet Erosion Apparatus Rotating Cylinder Electrode Apparatus with electrochemical interface as above. In this system, the hydrodynamics are well characterized. (Velocity range 1-8 m/s, particle size range from 50 to 750 um)

Rotating Cylinder Electrode Apparatus

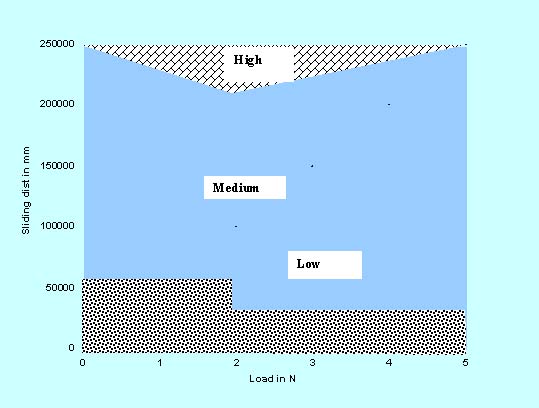

Micro-Abrasion Apparatus (Plint TE66). This facilitates abrasion tests for very small particle sizes-in the order of 10um. There is no restriction on particle shape.( Load range 1-5 N, Rotational speed range 50-150 rpm). This has applications to many areas of tribology, in particular to micro-abrasion in hip and knee joints. Micro-abrasion-corrosion maps in aqueous environments are being constructed using results from this rig.

Plint Micro-Abrasion Apparatus (Plint TE66) Pin on ring apparatus for sliding in corrosive conditions. This standard apparatus, with a long history in the tribology literature, has been modified in order to assess the corrosion rate in the sliding contact, in an aqueous medium. An ACM potentiostat is attached to the rig in order that controlled measurements of current density may be made at various electrochemical potentials. This enables the individual corrosion and wear contributions to be evaluated for the various materials, under exposure, at a range of applied loads, velocities and pHs.

Micro-Abrasion Wastage Map for Mild Steel Other facilities Other facilities available include those for micro-hardness and fatigue. In addition there is a vast range of analytical equipment available on site i.e. Transmission Electron Microscopy (TEM) Scanning Electron Microscopy (SEM) Atomic Force Microscopy (AFM) X Ray Diffraction (XRD) and Energy Dispersive X Ray Analysis (EDX) for chemical analysis.

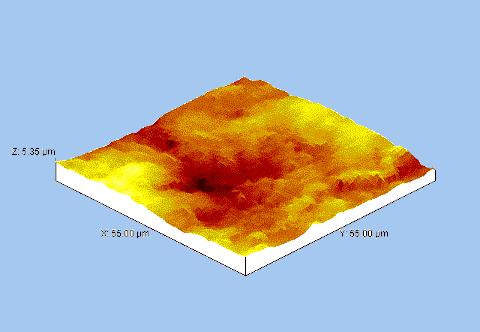

3-D AFM image of eroded WC/Co-Cr sample ( impact angle, 22.5 degrees) at 5 m/s showing removal of WC from the surface. Modelling research The department has a long history of expertise in mathematical modelling of solid particle erosion and one of the most well known models developed in the 1960s -that of Neilson and Gilchrist-was the work of two former members of academic staff in the department, one of whom (Alistair Gilchrist) has only recently retired. This work continues today. Finite element models are being developed to predict the complex effects of component geometry on erosion in flowing conditions. Research is also being carried out on the development of predictive models of erosion/ wear in corrosive conditions to generate mechanistic maps of the process. As stated above, these are important engineering tools which are designed to avoid the deleterious effects of tribo-corrosion. This group has established a lead in this area and is responsible for much of the recent developments in modelling and mapping of erosion-corrosion processes.

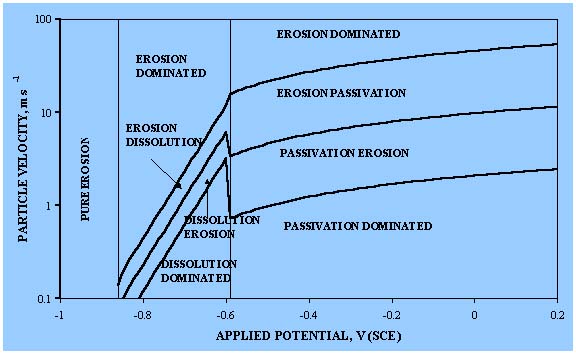

Erosion-Corrosion Mechanism Map for Fe using Sundararajan's model for Erosion at 90 Degrees at pH 7 .

Erosion-Corrosion Wastage Map for Fe using Sundaraarajan's Model for Erosion at 90 degrees at pH 7. List of current Projects Micro-abrasion-corrosion mapping of pure metals in aqueous slurries Micro-abrasion mapping of bio-materials Mapping micro-abrasion interactions in bio-oils Nanoscale studies of erosion-corrosion of "superlattice" PVD coatings in aqueous conditions An impinging jet study of the erosion-corrosion of MMC composite based coatings in aqueous conditions Predictive modelling of erosion-corrosion of metallic and composite materials in aqueous slurries Sliding wear-corrosion mapping in aqueous conditions Effects of applied load on the sliding-wear-corrosion map in aqueous conditions Tribo-Corrosion network (TrICorr-Net) : TrICorr-Net Conferences |

|

Matthew T Matthew PhD Title: Micro-abrasion-corrosion mapping in aqueous conditions. Although there has been recent interest in the performance of materials under micro-abrasive conditions, there has been very little work carried out to study these materials in corrosive conditions. The object of this work is to investigate the micro-abrasion behaviour of a range of material couples in corrosive environments using the PLINT TE 66 micro-abrasion apparatus. The variables considered in the work tested include rotation speed, applied load, electrochemical potential and pH and the materials tested include steels, HVOF "cermet" based coatings and polymer based composites. Work on micro-abrasion in bio-oils is also being carried out. The results are being used to construct wear-corrosion maps for the micro-abrasion-corrosion interaction. We gratefully acknowledge Weir Pumps (Dr Len Phillips) for provision of test materials involved in this project.

|

|

Yashodhan Purandare CO-Supervisor: Dr Papken Hovespean, Materials Research Group, Sheffield Hallam University PhD Title: Nanoscale studies of mechanisms of erosion-corrosion of "superlattice" PVD coatings New generation "superlattice" PVD coatings developed by the Surface Coatings group in Sheffield Hallam University have shown promising performance compared to conventional multilayered coatings. However, there has been very little work carried out to assess the performance in combined tribological and corrosive environments. The aim of this work is to carry out a systematic study of the erosion of CrN/NbN coatings at a range of pH and electrochemical potentials using Atomic Force Microscopy (AFM) to characterize the eroded surface. Erosion-corrosion maps are being constructed on the basis of this work. Sheffield Hallam University provide the coated specimens for this project and carry out development work based on the experimental results.

|

|

Buddhadev Jana PhD Title: Mathematical modelling of erosion-corrosion of metallic materials in aqueous slurries Particulate erosion-corrosion in aqueous slurries is a major problem in many industries ranging from off shore to health care environments. In such cases, mathematical modelling involves many variables ranging from parameters relating to the impacting particle, the target and the nature of the corrosive environment. The purpose of this work is to develop a predictive model of erosion-corrosion which enables the construction of erosion-corrosion maps for a range of metallic and composite based materials. Materials selection maps are being generated based on the results. The model will be tested against laboratory results from erosion-corrosion test rigs in the department. |

|

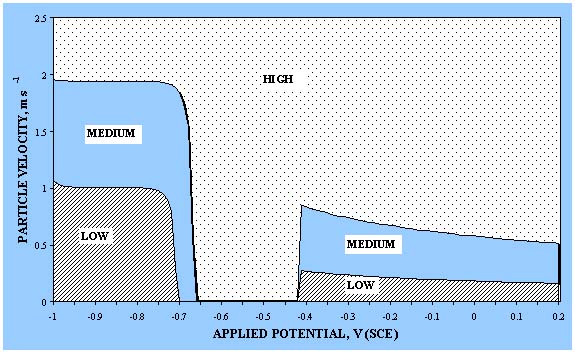

Ivan Olmo Erasmus project Effects of applied load on the sliding wear-corrosion map in aqueous conditions New work on the development of the wear map for aqueous conditions

has demonstrated a basis for defining wear-corrosion regimes as

a function of applied potential and velocity. However, the effect of

applied load on the transition boundaries may result in some

frictional heating effects, which, in turn, may change the wear-corrosion

regimes. The purpose of this work is to investigate the effect of

applied load, potential and velocity on the wear-corrosion of Fe in

aqueous solution. Wear-corrosion maps as a function of these

parameter are being developed based on the results. |

|

Keith Purvis Undergraduate student project Title: An impinging jet study of the erosion of MMC based coatings in aqueous conditions Aim: The aim of this project is to investigate the performance of MMCs in aqueous conditions, where erosion is caused by impact of solid particles in an impinging jet. The results will be used to assess the effect of erosion variables such as impact angle on a range of MMCs. Erosion maps will be constructed in these environments, showing the mechanisms of wastage as a function of the main process parameters.

|

|

Investigator: Professor Weiiju Huang Collaborator: Professor M.M. Stack Visiting Professor from Department of Material Science and Technology (Vice-Dean), Chongqing Institute of Technology, Chongqing, Peoples Republic of China Title: Micro-abrasion mapping of materials in bio-oils Bio-oils are promising lubricants in many tribological conditions; however, there has been very little study of their performance in micro-abrasion conditions. The purpose of this project is to investigate the mechanisms of micro-abrasion of various metallic materials in various bio-oils. Micro-abrasion maps will be constructed for the materials in the presence and absence of the lubricants. The transition between micro-abrasion regimes, from 3 body rolling to 2 body grooving will be assessed in such conditions. The group is grateful to the Chongqing Institute of Technology for sponsorship of this collaborative project.

|

|

Investigator: Dr Hosen Jawan Collaborator: Professor M.M. Stack Visiting Academic, Department of Mechanical Engineering, College of Engineering, University of Al Mrkeb, Libya Title: Micro-abrasion mapping of bio-materials in corrosive conditions Micro-abrasion-corrosion interactions are of particular interest for bio-material applications such as knee and hip joint prostheses. In such cases, the presence of micron sized particles may enhance the wear of the artificial hip joint. Developing a rationale for describing such interactions is a potentially useful engineering tool to controlling the damage. The aim of this work is to generate a micro-abrasion map in corrosive environments for a range of metallic materials. The group wish to acknowledge the Department of Mechanical Engineering, University of Al Mrkeb, for sponsorship of Dr Hosen's sabbatical. |

|

Dr Kuangnan Chi - Postdoctoral Researcher Title: Tribo-Corrosion network: TrICorr-Net. Sponsor: EPSRC Principal Investigator: Professor M.M. Stack CO-Investigators: Dr. R. Wood, University of Southampton Professor A. Neville, Heriot Watt University The aim of this project is to develop an academic/industrial Network for tribo-corrosion of materials, where the tribological interaction includes wear, erosion, abrasion and cavitation. Network activities include regular meetings on a series of topical issues in the area, both in the UK and overseas, in addition to developing collaborative grant applications. The proceedings of these meetings are being published on an ongoing basis. Links with academics in Europe, Canada and the US are also being developed as part of this project. |